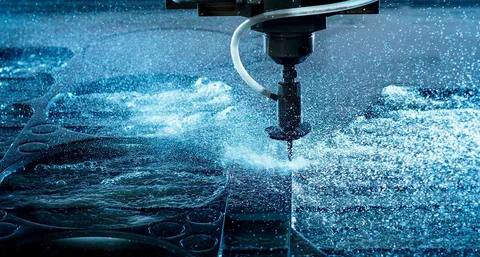

In today’s manufacturing world, precision is key. Waterjet cutting has become a go-to method for its ability to cut nearly any material—glass, steel, and more—with accuracy and minimal waste. Using high pressure and precise control, it delivers clean, smooth results across industries from aerospace to custom fabrication.

What Is Waterjet Cutting?

Waterjet cutting is a fabrication process that uses a high-pressure stream of water, sometimes mixed with an abrasive substance, to cut through materials. Unlike traditional cutting methods that generate heat, it is a cold-cutting process. That means it doesn’t cause heat-related damage, warping, or distortion to the cut material. There are two main types:

- Pure waterjet cutting uses only water, ideal for softer materials like rubber, foam, or paper.

- Abrasive waterjet cutting – adds substances like garnet to the water stream to cut through harder materials like metal, stone, and ceramics.

Benefits of Waterjet Cutting

- Versatility

One of the biggest advantages of waterjet cutting is its versatility—it can cut through a wide range of materials, including stainless steel, aluminum, titanium, glass, plastic, stone, and composites. This makes it an all-in-one solution for companies with diverse materials or requiring custom components.

- No Heat-Affected Zones (HAZ)

Waterjet cutting is a cold process, eliminating the risk of heat distortion or metal hardening. This is especially important when working with materials sensitive to high temperatures or requiring post-cutting machining.

- Precision and Accuracy

Waterjet systems can produce incredibly detailed and intricate cuts, with tolerances as tight as ±0.003 inches. This level of precision is ideal for components that require exact specifications, such as aerospace parts or medical devices.

- Minimal Waste

Waterjet cutting is known for its material efficiency. With a narrow kerf (cut width) and the ability to nest parts closely together, you can reduce waste and save on material costs. This is both economically and environmentally beneficial.

- Clean Edges and Minimal Finishing

Since waterjet cutting doesn’t cause burrs or rough edges, many parts require little to no additional finishing. This reduces labor time and speeds up the production process.

Applications of Waterjet Cutting

Waterjet cutting is used across various industries thanks to its adaptability. Here are a few key examples:

- Aerospace: For cutting high-performance metals like titanium and composites used in aircraft components.

- Automotive: To produce parts precisely, from engine components to interior panels.

- Architecture and Art: For custom stone inlays, metal signage, and decorative installations.

- Medical Equipment: To create surgical tools and precise machinery parts without heat damage.

- Manufacturing: Custom parts, prototypes, and production runs require tight tolerances.

Waterjet cutting offers an efficient, scalable solution, whether you’re a large manufacturer or a custom fabricator.

How the Waterjet Cutting Process Works

Waterjet cutting works by pressurizing water up to 60,000 psi and focusing it through a fine nozzle. For tougher materials, abrasives like garnet are added to enhance cutting power. Guided by CNC systems, the high-speed stream follows a programmed path to deliver precise, repeatable cuts.

Sustainability and Waterjet Cutting

Modern manufacturers are increasingly focused on sustainability, and waterjet cutting supports those goals in multiple ways:

- Recyclable abrasives – Some systems allow abrasive materials to be cleaned and reused.

- Reduced waste – Tight nesting of parts and precision cuts mean fewer leftover scraps.

- No toxic fumes – Unlike other cutting methods, Waterjet cutting doesn’t produce harmful gases or fumes.

These factors make it a responsible choice for companies prioritizing environmental impact alongside performance.

Ready to Cut Smarter?

Waterjet cutting is a smart choice if your project demands precision, clean edges, and the ability to cut various materials. Whether you’re producing custom parts or managing high-volume runs, its flexibility and reliability make it a valuable asset.

Waterjet cutting stands out as industries seek advanced, efficient, and sustainable solutions. With no heat damage, minimal finishing, and compatibility across materials, it helps businesses deliver better results—faster.